Introduction

Automobile engineering in Nigeria requires a strong emphasis on practical skills for success.

These skills are crucial for solving real-world problems and advancing in the field.

Understanding Basic Automotive Systems

Overview of essential automotive systems such as engine, transmission, brakes, and steering.

Importance of understanding how these systems work together in a vehicle.

Engine System

The engine is the heart of a vehicle, converting fuel into power for propulsion.

Understanding how the engine operates is crucial for diagnosing and fixing issues.

Components such as pistons, cylinders, and spark plugs work together to generate power.

Transmission System

The transmission system transfers power from the engine to the wheels.

Different types of transmissions include manual, automatic, and continuously variable.

Knowing how to optimize gear shifting and fluid levels improves performance.

Braking System

Brakes are essential for stopping and controlling a vehicle’s speed.

Components like brake pads, rotors, and calipers need regular maintenance.

Understanding how to inspect and repair brake systems ensures safety on the road.

Steering System

The steering system allows drivers to control the direction of a vehicle.

Components like tie rods, steering columns, and power steering assist in turning.

Proper alignment and steering wheel adjustments are key for safe driving.

Implications for Automotive Engineering in Nigeria

Having a solid understanding of basic automotive systems like the engine, transmission, brakes, and steering is essential for automobile engineering in Nigeria.

By mastering these systems and their interactions, engineers can effectively diagnose, repair, and maintain vehicles to ensure optimal performance and safety on the roads.

Remember, continuous learning and hands-on experience are key to mastering these practical skills in the field of automobile engineering.

Hands-on Experience with Diagnostic Tools

Having hands-on experience with diagnostic tools is crucial for automobile engineers in Nigeria.

It allows them to efficiently identify and troubleshoot issues in vehicles, ensuring optimal performance and safety on the roads.

Importance of Learning How to Use Diagnostic Tools

Learning how to use diagnostic tools enables engineers to quickly pinpoint issues in vehicles, saving time and resources.

By using diagnostic tools, engineers can accurately diagnose problems in vehicles, ensuring the right solution is implemented.

Being able to efficiently troubleshoot and fix issues using diagnostic tools leads to satisfied customers who trust in the engineer’s expertise.

Overview of Common Diagnostic Tools Used in Automobile Engineering

- OBD-II Scanners: OBD-II scanners are essential tools that read the onboard diagnostics system in modern vehicles, providing valuable information on the vehicle’s health.

- Multimeters: Multimeters are versatile tools used to measure voltage, current, and resistance in electrical systems, helping diagnose electrical issues in vehicles.

- Compression Testers: Compression testers are used to measure the compression levels in the engine cylinders, helping identify engine performance issues.

- Fuel Pressure Gauges: Fuel pressure gauges are used to measure the pressure of fuel in the fuel system, diagnosing fuel delivery issues in vehicles.

- Infrared Thermometers: Infrared thermometers are handy for measuring temperature variations in various vehicle components, detecting overheating issues.

- Smoke Machines: Smoke machines are used to detect vacuum leaks in the engine system by releasing smoke that shows the source of leaks.

- Scan Tools: Scan tools are advanced diagnostic devices that can access and analyze the vehicle’s computer systems, providing comprehensive data on the vehicle’s health.

- Circuit Testers: Circuit testers help engineers test for continuity and locate electrical faults in circuits, ensuring proper functioning of electrical systems.

- Borescopes: Borescopes are inspection tools used to visually inspect hard-to-reach areas in the vehicle’s engine and other components, aiding in diagnosis.

- Pressure Testers: Pressure testers are used to check for leaks in various systems such as the cooling system or the fuel system, ensuring proper functioning.

Explore Further: Agricultural Engineering and Climate Change Solutions

Training in Automotive Repair and Maintenance

Hands-on training in automotive repair and maintenance is crucial for automobile engineers in Nigeria.

This type of training allows them to develop practical skills that cannot be learned solely through theoretical study.

By working directly on vehicles, engineers can gain valuable experience and proficiency in diagnosing and fixing various issues that may arise.

Importance of Hands-on Training in Repairing and Maintaining Vehicles

Automobile engineers need to be able to identify issues with engine performance and determine the root cause of the problem.

Overview of Basic Repair and Maintenance Tasks That Automobile Engineers Should Be Proficient In

Diagnosing and troubleshooting engine problems is essential for efficient vehicle operation.

Changing oil and filters is vital for maintaining engine health.

Regular oil changes are essential for maintaining engine health, and engineers should be proficient in this basic maintenance task.

Replacing brake pads and rotors is critical for safety, so engineers must know how to replace worn brake components.

Checking and replacing spark plugs plays a crucial role in engine ignition.

Engineers should know how to inspect and replace them when necessary.

Conducting routine vehicle inspections is essential for identifying potential problems or areas of concern.

Engineers should be able to perform comprehensive inspections of vehicles.

Repairing electrical systems is increasingly important in modern vehicles.

Engineers need to understand how to diagnose and repair issues with these complex electrical systems.

Performing wheel alignments and tire rotations ensures safe and efficient driving.

Transform Your Career with Expert Guidance

Get personalized mentorship consulting that’s tailored to your unique path. Our expert advice is actionable and exclusive.

Get StartedEngineers should be skilled in these tasks.

Servicing and repairing air conditioning systems is vital, especially in hot and humid climates like Nigeria.

Engineers should know how to service and repair air conditioning systems to ensure passenger comfort.

Overall, hands-on training in automotive repair and maintenance is essential for automobile engineers in Nigeria.

By mastering basic repair and maintenance tasks, engineers can ensure the safe and efficient operation of vehicles on Nigerian roads.

You Might Also Like: Government Policies on Systems Engineering in Nigeria

Developing Welding and Fabrication Skills

Learning welding and fabrication techniques is crucial for repairing vehicle bodies and structures.

It is essential to have knowledge of common welding and fabrication techniques used in automobile engineering.

Importance of Welding and Fabrication Skills

Welding and fabrication skills are fundamental for automobile engineers in Nigeria.

These skills are required for repairing and maintaining vehicle bodies and structures.

Without these skills, it would be challenging to handle repairs effectively.

Overview of Common Welding and Fabrication Techniques

There are several welding and fabrication techniques that automobile engineers in Nigeria should be familiar with.

- Gas Metal Arc Welding (GMAW): Also known as MIG welding, this technique uses a wire electrode to join metal parts together.

- Gas Tungsten Arc Welding (GTAW): This technique, also known as TIG welding, uses a non-consumable tungsten electrode to weld metal.

- Shielded Metal Arc Welding (SMAW): Commonly known as stick welding, this technique uses a coated electrode to join metal parts.

- Flux-Cored Arc Welding (FCAW): This technique is similar to MIG welding but uses a tubular electrode filled with flux to shield the arc.

By mastering these welding and fabrication techniques, automobile engineers in Nigeria can effectively repair and maintain vehicle bodies and structures.

This ensures the safety and performance of the vehicles they work on.

You Might Also Like: Success Stories of Nigerian Agricultural Engineers

Enhancing Electrical and Electronics Skills

Understanding electrical and electronic systems in modern vehicles is crucial for automobile engineers in Nigeria.

Here is an overview of the basic electrical and electronic skills needed for automobile engineering:

Importance of Understanding Electrical and Electronic Systems

- Modern vehicles are becoming increasingly reliant on electrical and electronic components.

- Engineers need to understand how these systems work to diagnose and repair issues effectively.

- Electrical and electronic skills are essential for staying up-to-date with technological advancements in the automotive industry.

- Having a strong foundation in this area can lead to better job opportunities and career growth.

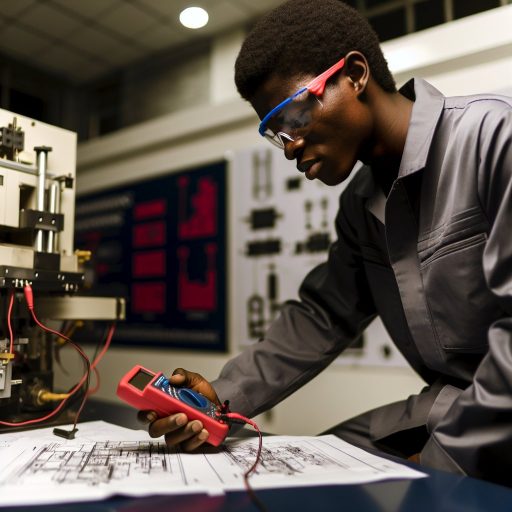

Overview of Basic Electrical and Electronic Skills

- Knowledge of electrical circuits and wiring diagrams is fundamental for troubleshooting electrical problems.

- Understanding different types of sensors and actuators used in vehicles is essential for proper functioning.

- Familiarity with diagnostic tools and equipment for testing electrical systems is crucial for accurate diagnosis.

- Ability to interpret and analyze data from onboard computers and electronic control units (ECUs) is necessary for efficient repairs.

- Skills in soldering and crimping wires, as well as connecting and disconnecting electrical components, are important for repairs and installations.

- Proficiency in using multimeters, oscilloscopes, and other testing devices is essential for troubleshooting electrical issues.

- Knowledge of automotive electrical systems, including batteries, alternators, starters, and lighting systems, is vital for maintenance and repairs.

- Understanding electrical safety practices and regulations is crucial to prevent accidents and ensure personal safety in the workshop.

By enhancing their electrical and electronics skills, automobile engineers in Nigeria can effectively diagnose and repair electrical issues in modern vehicles.

These skills are essential for staying competitive in the automotive industry and providing high-quality services to customers.

Uncover the Details: The Role of Metallurgical Engineers in Nigeria’s Oil Industry

Skills for Automobile Engineering in Nigeria

Proficiency in electrical systems is essential for engineers in this field.

Engine diagnostics knowledge helps identify and solve mechanical issues.

Computer software proficiency enhances problem-solving capabilities.

Understanding automotive design principles fosters innovation.

Welding and fabrication skills are crucial for hands-on tasks.

Continuous learning is vital for staying competitive in the industry.

Automobile engineers should adapt to new technologies rapidly.

Building a strong skill set positions engineers for career growth.

Commitment to lifelong learning opens opportunities for advancement.

By mastering practical skills, engineers can contribute significantly to the industry.

Additional Resources

Joy Ijagun – Engineer – Generative CAD Services Limited | LinkedIn